The more versatile the material - the more people opt for a wooden boat

Vendia's development program aims to develop even more sustainable products. We are developing new materials from finnish northern pine, that are not only more beautiful and ecological, but also more affordable in terms of life cycle costs.

Development activities

Vendia Woods develops ecological boatbuilding materials that meet the requirements of modern boatbuilding. As part of the development program launched in 2023, various surface treatments and materials are developed and tested, alternative interior structures are experimented with, and the alternatives are tested in a wood laboratory. In addition to the materials, Vendia is developing digital production processes that make it possible to customize Vendia materials as much as possible and thus save the time needed to build boats. Part of being a sustainable company is reducing raw material waste, which is why Vendia has set up product development workshops with local craftsmen.

Vendia's development program is supported by the European Union's regional structural funds as part of the Green Transition Development Fund (https://rakennerahastot.fi/uudistuva-ja-osaava-suomi-2021-2027).

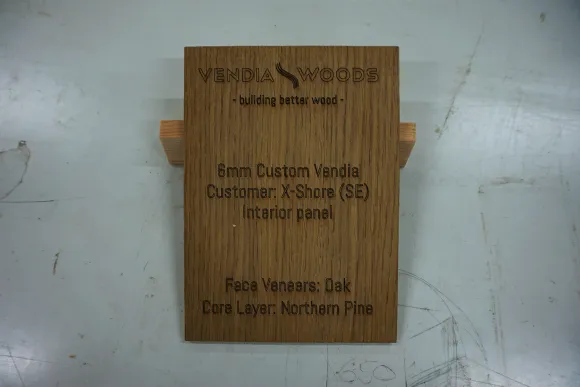

Development of material variations

Vendia is experimenting with different types of colored pine veneers, investigating the workability of heat-treated pine wood and testing different lignin-based surface treatment materials - the new surface material must be easy to work with, for example, it must be possible to sand even colored veneers. “Lignin-based surface treatments replace fossil-based materials, but must also improve the properties of the wood, e.g. the fire resistance of interior solutions" says Jouka Dehm.

Custom Interior solutions

Vendia's boat panels are developed for boat building. We are developing and testing various new interior structures that either reduce manufacturing costs or are more suitable for the intended purpose. For example, we are experimenting with the use of Paulownia wood when lightness is important, such as in electric boats and sailing boats. We are also experimenting with different lignin-based adhesive options that can be an alternative to the fossil-based MUF adhesive, now used by Vendia (link to the data sheet about the adhesive).

Testing of products in development

New surface materials and internal structures are tested in a variety of laboratory tests. Flexibility, compressibility, stretchability and resistance to extreme conditions are tested and measured. The measurement results are used to apply for the CE marking required for the serial production of boats. Our partner is XAMK.

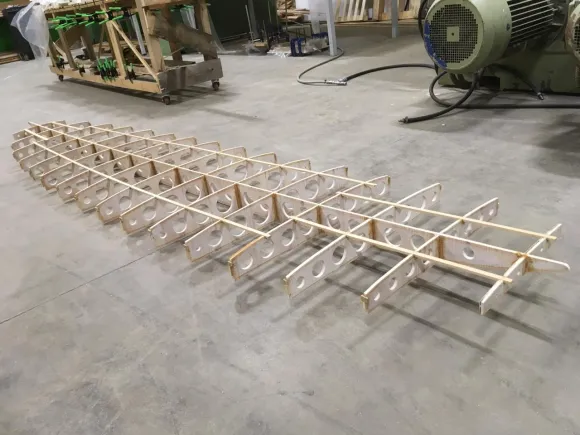

Digital production methods

Vendia already produces CNC machined planks and panels according to the customer's digital drawings. Our canoe kit is also pre-machined. We are further developing our machining capabilities by digitalizing the traditional Käenniemi rowing boat and our own Kayak for hobby builders.

Utilization of material side streams

Vendia produces materials tailored to the customer's dimensions, which makes boat building more efficient, but at the same time Vendia also wastes material. Basket weavers already use our veneers, but efficient use of the valuable material requires other uses, and we are working on those already.